Q NET Quality Network Pvt Ltd offers wide range of Inspection for all major Industries in the global market.

QNET India can provide standard and custom-designed Ultrasonic and Eddy current equipment for a large variety of testing applications.

Read More

We advise on nondestructive evaluation techniques and perform NDT services for industry and R&D organizations.

Read MoreOur Products

In collaboration with the Fraunhofer Institute for Non-Destructive Testing (IZFP), Q NET has developed an ultrasonic method for fast and non-destructive case depth testing..

Read More

Our Powerful and intelligent ultrasonic testing systems are indispensable for ISI inspections. These systems should be usable for stationary, in situ applications and must be suited to the individual inspection task to ensure high inspection standards. In addition, they must be easy and quick to setup and use..

Read More

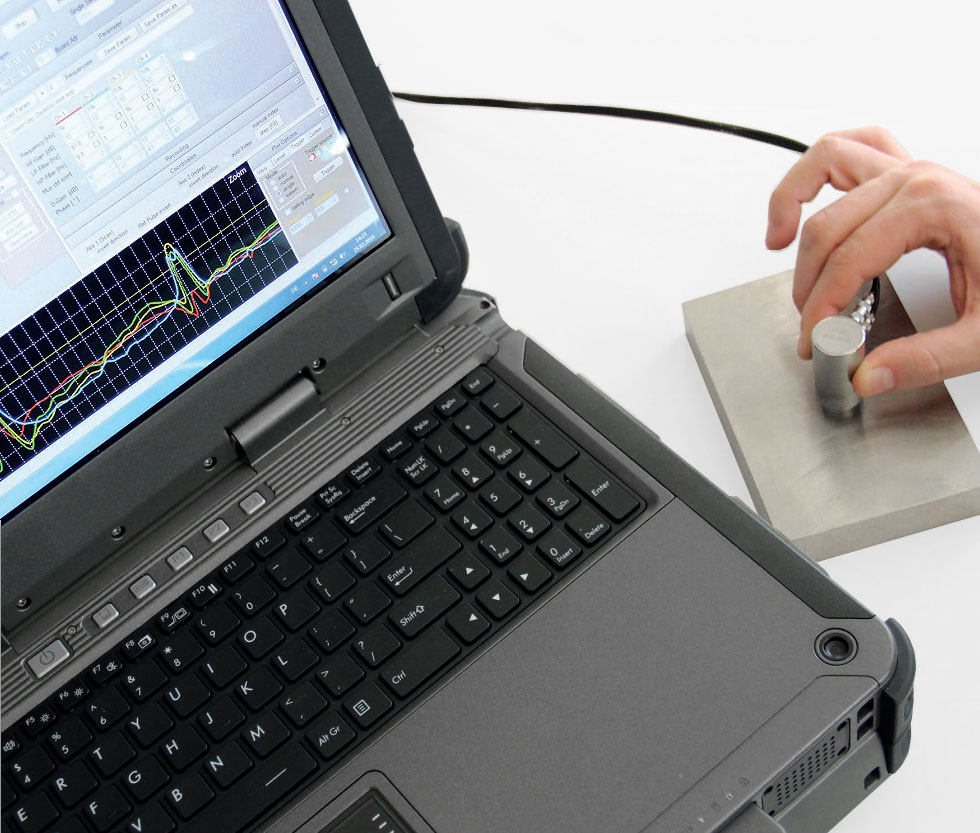

The PCUS®pro single-channel ultrasonic frontend is designed to meet requirements of high data acquisition rates and high inspection speeds.

Read More

The PCUS®pro multi-channel ultrasonic frontend is designed to meet requirements of high data acquisition rates and high inspection speeds..

Read More

The PCUS®pro Array ultrasonic frontend is designed to meet requirements of high data acquisition rates and high inspection speeds..

Read MoreServices

QUALITY & ENVIRONMENTAL POLICY

MAJOR CLIENTS

WRITE TO US

CONTACT US

Quality Network Pvt Ltd.

Works

No. 10, II Cross Street, Kalaimagal Nagar,

Ekkattuthangal, Chennai - 600032

Registered Address

#38/GA, Shoreham, 5th Avenue, Besant Nagar,

Chennai – 600 090

Phone: +91 44 4857 5263

Mob: +91 9444979858

NETWORK

11 Main Street

Sparta, NJ 07871-1979

Phone: +01 (973) 726-8399

Mobile: +01 (973) 699-4460

Email: md@qnetworld.com

Web: www.qnetworld.com